Exploring the Side Planer Moulder

The Side Planer Moulder is a woodworking apparatus engineered for precision in cutting, shaping, and planing wood and other materials. It is indispensable for woodworkers, artisans, and manufacturers who demand the creation of uniform, flat surfaces and accurately sized lumber, mouldings, and other elements. Operating on the same principles as a planer, it employs a rotating cutter head to strip material from the workpiece, yielding a polished finish.

What sets the Side Planer Moulder apart from conventional planers are its additional capabilities, such as side spindles for intricate side cuts, enabling complex shaping and profiling. Equipped with multiple heads, these machines can perform planing, moulding, and even sanding, offering a versatile solution for a spectrum of woodworking tasks, from boutique artisanal projects to extensive factory production.

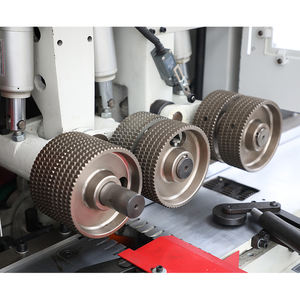

In operation, the Side Planer Moulder processes material by guiding it through the apparatus, where it is planed to the required dimensions. Feed rollers propel the material across the cutter head at a consistent speed, ensuring a uniform cut. High-end models may feature adjustable speeds, cutter heads, and digital readouts for meticulous control of the planing process. Designed with safety and productivity in mind, these machines incorporate protective measures and are engineered to smoothly process diverse wood types and materials.

Varieties of Side Planer Moulder

Side planer moulders are available in various forms to accommodate different woodworking requirements, each with distinct features tailored to specific tasks:

-

Handheld Side Planer Moulders: Compact and mobile, these machines are suitable for on-site carpentry, such as trimming doors or adjusting joints where larger machines are impractical.

-

Stationary Side Planer Moulders: These sturdy machines cater to high-volume production and are commonly found in spacious workshops.

-

Benchtop Side Planer Moulders: These small-scale, yet potent models are ideal for limited workshop spaces or for on-site use where portability and swift setup are crucial.

-

Automatic Side Planer Moulders: Suited for industrial-scale lumber processing, these machines deliver uniform results with minimal oversight and are often part of assembly lines in furniture manufacturing or building material outlets.

Selecting a Side Planer Moulder

Choosing the right side planer moulder for your enterprise involves careful deliberation of several factors to ensure a sound decision. First, evaluate the material you will be processing; different woods may demand specific cutter profiles and machine capabilities for optimal outcomes. For example, tougher woods might require stronger motors or specialized cutter materials to mitigate wear.

Second, factor in your production volume. Machines differ in efficiency and capacity; selecting one that aligns with or surpasses your present and anticipated production needs will prevent the need for future investments or production delays due to limited capacity.

Finally, consider the space at your disposal. Certain models offer space-efficient features such as sliding tables or compact designs, which can be particularly beneficial for smaller areas or crowded production environments.

About Side Planer Moulder on Alibaba.com

Alibaba.com is a comprehensive marketplace that connects global buyers with a plethora of suppliers, offering a broad selection of products, including side planer moulders. For businesses in search of effective woodworking solutions, Alibaba.com grants access to an extensive range of machines to satisfy various production needs. The platform's expansive network ensures that no matter your location, from Colombia to Australia, you can procure industrial-grade machinery tailored to your operational requirements.

Alibaba.com enhances the business experience with services like Trade Assurance, which safeguards payments until delivery confirmation, providing buyers with confidence when purchasing complex machinery such as side planer moulders. Additionally, with support for local languages and mobile-friendly purchasing options, Alibaba.com streamlines transactions, positioning itself as a comprehensive hub for wholesale trade.

Opting for Alibaba.com as your procurement platform not only offers competitive prices but also connects you with a community that prioritizes quality and dependability in international commerce. This dedication is evident in Alibaba.com's stringent supplier verification process, which ensures that businesses receive products that adhere to their high standards of quality and efficiency.

Common FAQs for Side Planer Moulder

What is the purpose of a side planer moulder?

A side planer moulder is chiefly employed to render wooden boards or panels with smooth and flat sides, rendering them apt for diverse applications in furniture production, cabinetry, and other woodworking domains.

How does a side planer moulder function?

A typical side planer moulder utilizes a singular, swiftly rotating cutter head to flatten the length of a workpiece by excising material with each pass.

What are the principal varieties of side planer moulder machines?

Key types encompass manual, power, and automatic side planer moulders, each designed to cater to varying levels of production volume and automation requirements.

What considerations are important when selecting a side planer moulder for my enterprise?

Key considerations include production volume, material type, desired surface finish quality, operational simplicity, and the availability of after-sales support.

Can a side planer moulder accommodate various materials?

Most side planer moulders are adaptable and capable of handling a range of materials, from softwoods and hardwoods to plywood, MDF, and assorted panel materials.

How can I ensure the side planer moulder I select is compatible with my existing machinery?

Verify the specifications of the side planer moulder to confirm compatibility with your current equipment, which is crucial for seamless integration and peak performance.

What maintenance is required for a side planer moulder?

Routine maintenance generally involves cleaning the machine, inspecting blade wear, aligning the cutter head accurately, and lubricating moving components.

Are there various cutter head options for side planer moulders?

Indeed, there are multiple cutter head choices, such as straight knife and helical cutter heads, to suit the specific demands of your projects.

Is it feasible to obtain a machinery test report for a side planer moulder prior to purchase?

Certain suppliers may offer machinery test reports. It is advisable to request this documentation from the supplier to confirm that the machinery complies with industry norms and specifications.

What after-sales services are crucial for a side planer moulder?

Post-purchase considerations should include field maintenance and repair services, video technical support, online assistance, and the availability of local service locations from the supplier.

How do I ascertain the appropriate size side planer moulder for my business?

Assess the dimensions of the material you will be working with and the size of the side planer moulder. Machines are designed for varying sizes of workpieces, so make your selection accordingly.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4