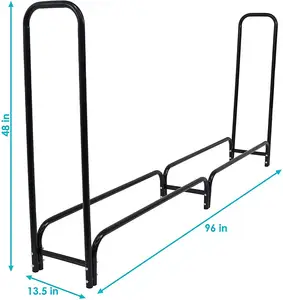

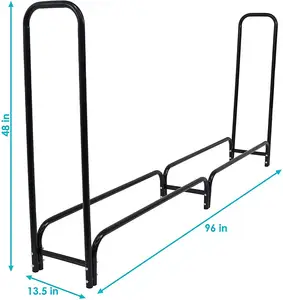

Outdoor 8 Feet Heavy Duty Firewood Rack Stand Fireplace Log Holder Firewood Log Storage Rack Bracket

A frame rack is a specialized piece of equipment used in automotive repair shops and collision centers designed to straighten and align vehicle frames and chassis. These towers apply controlled force to specific points on a vehicle's frame, allowing technicians to manipulate and restore the frame to its original shape and dimensions.

Steel is a primary material used in crafting frame racks due to its durability and strength. It is often used in the construction of heavy-duty frame racks capable of bearing substantial weight loads. Cold-rolled steel, known as SPCC (Steel Plate Cold Commercial), is also commonly utilized for its strength and versatility in manufacturing various rack types, especially those requiring resistance to bending or deformation. Stainless steel, renowned for its corrosion resistance, finds application in environments where rust or corrosion could be problematic. Additionally, aluminum is sometimes employed for its lightweight properties. Other materials, including composite materials or alloys, might be utilized in specialized or custom rack constructions.

Frame racks, whether they are the sturdier 4 post server racks or the more accessible 2 post rack servers, come with a range of features. Many frame racks are constructed with materials that offer corrosion protection, ensuring longevity even in challenging environments. Adjustable components are common, allowing for customization and adaptability to various equipment sizes and configurations. Additionally, these racks often feature open-frame designs, providing unrestricted access to mounted equipment for easy maintenance and cable management. Some frame racks offer mobility through casters or wheels, facilitating convenient relocation within a workspace. Cable management options such as integrated cable channels or tie-down points help organize and route cables neatly. Some models come with leveling feet or adjustable legs to ensure stability on uneven surfaces. Furthermore, accessories like shelves, blanking panels, or vented panels are available to tailor the racks for specific equipment and cooling needs.

In warehouse and logistics settings, pallet frame racks are commonly utilized for efficient storage of palletized goods. These robust frames, often part of larger storage systems, provide structural support for multiple levels of pallets, optimizing vertical storage space while allowing easy access to goods using forklifts or pallet jacks. Moreover, in the glass industry, A-frame glass racks offer a specialized solution for storing and transporting glass sheets or panels safely. Open frame racks find applications in data centers and IT environments, providing an organized structure for mounting servers, networking equipment, and other hardware. The open design allows for proper ventilation and easy access for maintenance. Specifically, 4 post open frame racks offer added stability and weight-bearing capacity, suitable for heavier IT equipment.