Introduction to 200kg Horizontal Ribbon Mixers

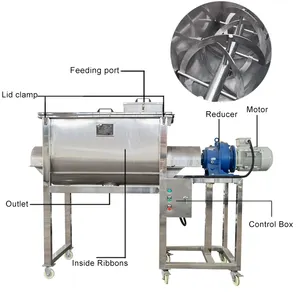

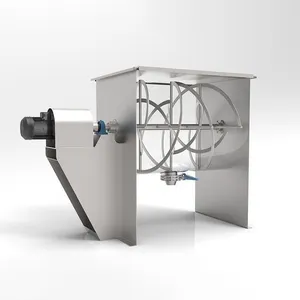

The 200kg horizontal ribbon mixer is a staple in the industrial mixing category, designed to blend a wide variety of dry solids, powders, and granular materials efficiently. This type of mixer is recognized for its u-shaped horizontal trough and a specially fabricated ribbon agitator. A ribbon mixer operates by moving materials in opposing lateral directions and radially. The design ensures a homogeneous mix, critical in many manufacturing processes.

Design and Operation

A ribbon blender is engineered with inner and outer helical agitators to ensure thorough mixing. The 200kg capacity model is compact yet powerful, making it suitable for small to medium-sized batches. The mixer's operation is straightforward, with a loading port at the top and a discharge gate at the bottom, facilitating a seamless production flow.

Materials and Construction

Constructed typically from stainless steel or carbon steel, industrial ribbon blenders are built to withstand the rigors of industrial environments. The choice of material depends on the nature of the materials to be mixed, with stainless steel being a popular choice for its resistance to corrosion and ease of cleaning.

Applications and Versatility

The versatility of a powder mixing machine like the 200kg horizontal ribbon mixer extends across various industries, including food, pharmaceuticals, chemicals, and construction. It is adept at mixing dry powders, granules, and even pastes, making it a versatile tool for businesses requiring consistent and uniform mixing.

Features and Advantages

A horizontal powder mixer boasts features such as a low-energy requirement, minimal maintenance, and ease of operation. Its design allows for near-complete discharge of materials, reducing waste and cross-contamination risks. The simplicity of the ribbon mixer's design translates to fewer moving parts, which equates to less wear and a longer lifespan for the equipment.

Choosing the Right Mixer

Selecting the appropriate batch powder mixing machine involves considering batch size, material characteristics, and mixing homogeneity requirements. The 200kg model provides a balance between batch volume and space efficiency, making it a prudent choice for many operations. While Alibaba.com facilitates the connection between buyers and a diverse range of suppliers, it is advisable to evaluate the mixer's specifications, material compatibility, and supplier reliability to ensure the equipment meets the specific needs of your process.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4