Popular in your industry

Top categories

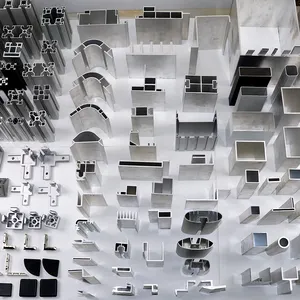

About aluminium extrusion profile enclosure

Introduction to Aluminium Extrusion Profile Enclosures

Aluminium extrusion profile enclosures are integral components in various industries, serving as protective frameworks for a multitude of applications. These enclosures are crafted through a process that pushes aluminum alloys through complex dies, resulting in precise profiles with uniform cross-sections. The versatility of aluminum profile enclosures makes them suitable for use in construction, machinery, electronics, and decorative fixtures.

Types and Applications

The applications of aluminium extrusion profile enclosures are diverse, ranging from structural components in building construction to intricate housings in electronic devices. Their adaptability is evident in their various forms, including hollow tubes, solid bars, angles, and complex locking systems. These profiles are essential in creating framing systems, sliding mechanisms, and even in the aesthetic enhancement of furniture.

Surface Treatments and Features

Surface treatments for aluminum profile enclosures enhance their durability and appearance. Options include anodizing, which provides a corrosion-resistant and decorative finish, and electrophoresis, which imparts a glossy sheen. Powder coating and PVDF coating are other popular treatments that offer additional color and protection, while wood grain finishes provide a natural aesthetic without compromising the material's inherent strengths.

Material Specifications and Advantages

Aluminium extrusion profiles are predominantly made from alloys, with temper variations from T3 to T8, signifying the material's hardness and strength. The advantages of using these enclosures include their lightweight nature, excellent corrosion resistance, and the ability to withstand extreme environmental conditions. Furthermore, their non-magnetic properties and thermal conductivity make them indispensable in electrical and thermal applications.

Customization and Versatility

The customization potential of aluminium extrusion profile enclosures is vast, with options to select from a range of shapes, sizes, and colors. This flexibility allows designers and engineers to tailor the profiles to specific requirements, ensuring that each enclosure meets the precise needs of its application. Whether for decorative purposes or functional use, these profiles can be adapted to suit any design aesthetic or technical demand.

Choosing the Right Profile

Selecting the appropriate aluminium extrusion profile enclosure is crucial for ensuring the longevity and effectiveness of the application it serves. Factors to consider include the environmental conditions it will face, the mechanical stresses it will endure, and the aesthetic qualities desired. With a comprehensive selection available, finding the right aluminum extrusion profile to meet the demands of any project is facilitated.