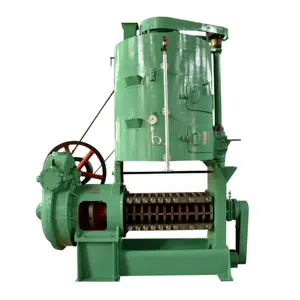

In the realm of commercial lard production, which is closely related to beef tallow oil extraction, professionals utilize specific machinery to optimize the process. The equipment employed for rendering lard can be adapted for beef tallow oil extraction, ensuring efficient separation and collection of the oil. A typical setup includes a grinder for processing fat trimmings, which is a crucial step also in beef tallow oil extraction. The ground fat is then heated in a large kettle, a process that parallels the extraction of beef tallow oil, where slow heating is essential to maintain the quality of the oil.

The subsequent stage involves the separation of oil from impurities, a step that is critical in both lard and beef tallow oil extraction. For lard, this is done using a draining spoon to remove cracklings and a cheesecloth for filtration. In beef tallow oil extraction machines, similar filtration systems are in place to ensure the purity of the oil. The settling tank mentioned for lard rendering, equipped with faucets at strategic levels to separate water and impurities from the oil, is also a common feature in beef tallow oil extraction equipment.

Moreover, the concept of compound lard, where pork lard is mixed with beef tallow to achieve a desired consistency, hints at the versatility of these machines. They can handle different types of animal fats, which is beneficial for businesses that aim to produce beef tallow oil. The mixing and agitation process described for lard is equally important in the extraction of beef tallow oil to achieve a uniform quality. This illustrates the multifunctional capability of the equipment, which can be a significant advantage for producers.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4