Popular in your industry

Top categories

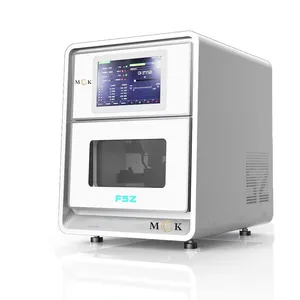

About cad cam dental machine

Exploring Dental CAD CAM Technology

The Dental CAD CAM Machine represents a sophisticated technological union of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM), streamlining the creation, analysis, and production of dental restorations. These systems are indispensable in crafting crowns, bridges, veneers, dentures, and other prosthetics, increasingly finding their place in both dental laboratories and practices.

At the heart of Dental CAD CAM Machines lies the capacity for exceptionally precise and intricate work, a non-negotiable in the realm of dentistry where exactitude is critical. The apparatus typically involves a computer-guided mechanism that converts digital designs into meticulous movements, directing a cutter or printer head to sculpt materials. This digitized method guarantees uniform, superior outcomes, vital for restorations that must seamlessly integrate into a patient's oral cavity.

Dental specialists, encompassing prosthodontists, orthodontists, and restorative-focused general dentists, employ these machines to produce bespoke dental restorations. The operational principles of these devices revolve around manipulating digital data, often sourced from intraoral scans or 3D models via CAD software. Subsequently, the machine mills or 3D prints the restorations with remarkable precision and dependability.

Varieties of Dental CAD CAM Machines

The marketplace offers a spectrum of Dental CAD CAM machines, each engineered to satisfy distinct clinical needs with particular features suited to diverse dental applications:

-

Milling Machine: Employed for carving dental prostheses from material blocks, milling machines boast versatility, working with zirconia, metal, and glass ceramics, and are commonly used for crowns, bridges, and implants.

-

Printing Machine: Dental 3D printers produce exact tooth and gum models, utilizing additive manufacturing to construct intricate structures from digital blueprints.

-

Scanning Machine: These instruments gather patient dental or gum data, transforming it into digital models, crucial for detailed treatment planning and tracking progress over time.

-

Grinding Machine: Also referred to as a burr machine, this equipment shapes or grinds materials like metal or zirconia to precise specifications, especially useful for fine-tuning restorations or preparing abutments.

-

Cutting Machine: Designed to trim excess material from restorations or to segment large material blocks, these machines often feature various cutting tools for diverse tasks.

Selecting a Dental CAD CAM Machine

In choosing a Dental CAD CAM machine for your practice, it's essential to weigh the specific demands of your patients against the desired operational efficiency. Key considerations include:

-

Material Compatibility: Verify the machine's ability to process the materials you plan to use, whether it's high-speed milling of metals or intricate carving of resins.

-

Accuracy and Precision: Custom fabrication demands unwavering accuracy. Seek out machines renowned for maintaining high precision and strict tolerances.

-

Workflow Integration: Assess how the machine will integrate with your current workflow. Some systems are designed for smooth compatibility with prevalent dental CAD software.

-

Support and Maintenance: Post-purchase support such as onsite training, spare parts availability, and quality certifications can be pivotal in your decision-making.

Acquiring a Dental CAD CAM machine is a substantial investment that necessitates a thorough assessment of your practice's needs and a careful examination of the diverse options on the market.

Dental CAD CAM Machines on Alibaba.com

Alibaba.com serves as a comprehensive marketplace that bridges buyers with global suppliers, presenting a wide array of Dental CAD CAM machines suitable for a variety of dental industry applications. The platform offers a multitude of choices from international suppliers, ensuring you find the right equipment that aligns with your business requirements without compromising on quality or efficiency. Whether in search of a compact desktop model for sporadic use or a robust industrial system for extensive production, Alibaba.com enables exploration of different models, prioritizing safety standards and quality certifications.

The platform's intuitive interface permits businesses to scrutinize specifications such as power source options, material compatibility including zirconia or PMMA, adherence to safety standards, and personalized support like OEM services. This ensures that businesses can secure machinery that meets their operational needs while adhering to industry norms and regulatory mandates.

Moreover, Alibaba.com underscores its commitment to secure transactions with services like Trade Assurance, which safeguards buyers by ensuring payments are protected until delivery confirmation. The multilingual website broadens accessibility for businesses worldwide. Alibaba.com's holistic approach to B2B sales and customer service empowers dental practices to augment their production capabilities with dependable and efficient CAD CAM solutions.

Frequently Asked Questions on Dental CAD CAM Machines

What functions does a dental CAD CAM machine serve in a dental practice?

A dental CAD CAM machine is chiefly utilized in dentistry for the precise crafting and production of dental prosthetics such as crowns, bridges, and implants, tailored to individual patient needs.

What is the operational mechanism of a CAD CAM machine?

A CAD CAM machine operates by capturing digital or scanned impressions of a patient's oral cavity, employing specialized software for prosthetic design, and then executing the fabrication with CAM technology.

Which materials are compatible with a dental CAD CAM machine?

Dental CAD CAM machines can accommodate a variety of materials, including zirconia, titanium alloys, ceramics, and resins, contingent on the machine's specific model and features.

What are the essential capabilities to consider when selecting a dental CAD CAM machine?

When selecting a dental CAD CAM machine, essential capabilities to consider are the machine's proficiency in handling intricate 3D designs, its precision for accurately fitting restorations or prosthetics, and its material versatility.

Is it possible to integrate dental CAD CAM machines with existing dental practice management systems?

Many dental CAD CAM machines are engineered to be compatible with practice management systems, enabling direct transmission of designs to milling or manufacturing apparatus.

What safety standards should a dental CAD CAM machine meet?

Dental CAD CAM machines should conform to relevant international safety standards such as ISO 13485, as well as national regulations like Gb15979-2002 or MFDS for South Korea, depending on the machine's geographical location and intended application.

How should one decide between a desktop and an in-clinic dental CAD CAM machine?

The decision between a desktop and an in-clinic dental CAD CAM machine should be based on factors such as the volume of work, space constraints, user-friendliness, system compatibility, and the preference for portability in scenarios like house calls or mobile clinics.

Are there specific maintenance protocols for dental CAD CAM machines?

Yes, dental CAD CAM machines require regular upkeep to maintain optimal performance, which typically involves routine cleaning, software updates, and mechanical component servicing.

How is customization applied to dental CAD CAM machines?

Customization of dental CAD CAM machines can encompass software tweaks, hardware alterations, or tailor-made components to satisfy particular needs, allowing machines to be adapted for branding purposes or specialized clinical requirements.

Can dental CAD CAM machines mill materials other than dental prosthetics?

Although these machines are primarily designed for dental purposes, they may be capable of processing a range of materials. It is advisable to consult the manufacturer to verify the machine's suitability for other materials safely and effectively.

What kind of post-sale services are typically offered for dental CAD CAM machines?

Post-sale services for dental CAD CAM machines vary among suppliers but can include complimentary spare parts, return and replacement policies, onsite training or installation, and options for onsite inspections or maintenance.