Popular in your industry

Top categories

About clear coat sealer

Introduction

Woodwork, whether indoor furniture or outdoor structures, is an investment that adds value and beauty to your space. However, to maintain its charm and longevity, it requires protection from elements such as moisture, UV rays, and daily wear and tear. This is where clear coat sealers come into play. They not only preserve the aesthetic appeal of your woodwork but also enhance its durability. This article delves into the importance of clear coat sealers, the different types available, and how to choose the right one for your specific needs. We also explore the application process and how to maintain your sealed woodwork for years to come.

Understanding the Importance of Clear Coat Sealers

Clear coat sealers play a crucial role in protecting surfaces, with factors such as indoor or outdoor use, ease of application, and environmental safety being key considerations. Artisan Enhancements™ offers non-toxic, high-performance, and bio-sustainable professional coatings developed from renewable and sustainably sourced ingredients. Their Clear Topcoat Sealer and Clear Finish are popular among DIYers, artists, and professional painters. These protective coatings offer a variety of uses and benefits, making them an excellent choice for preserving the beauty of your woodwork.

Different Types of Clear Coat Sealers

Clear coat sealers come in various types, each with its unique properties. The two basic types are water-based and oil-based sealers. Water-based clear coats are easy to clean, have low odor, and their finish is less likely to change over time. They dry quickly and can be used on bare, stained, or painted wood. On the other hand, oil-based sealers are traditionally used on furniture, providing a durable finish. However, some oil-based sealers might leave a yellow haze on white pieces or hazy streaks on dark furniture. Polyurethane sealers, often referred to as 'poly' finish or topcoat, are another popular choice, providing a shield against scratches, water rings, and dirt.

Oil-Based Sealers

Oil-based sealers are a type of clear coat sealer that can provide depth and color to wooden projects. They are particularly effective for wood that benefits from an orangy/amber tint, as they can enhance these natural hues. However, they have a tendency to yellow over time, especially when applied over paint. This can lead to a streaky, unattractive finish that may require you to redo your entire project. Therefore, while oil-based sealers can be a good choice for certain wood types, they should be used with caution.

Water-Based Sealers

Water-based acrylic sealers have evolved significantly, debunking the myth of their inferiority to solvent-based sealers. They are tough to remove, proving their durability. These sealers are environmentally friendly, emitting no volatile organic compounds (VOCs), making them a healthier choice. They can be applied with a typical garden sprayer and do not darken the surface like solvent-based sealers. However, they have a narrower effective temperature range and are best used indoors. Despite some disadvantages, their benefits make them a viable choice for those seeking sustainable options.

Polyurethane Sealers

Polyurethane sealers, available on Alibaba, are a popular choice for wood finishes. They come in various forms, including oil-based and water-based, catering to different needs. Brands like Varathane, BEHR, and Rust-Oleum Parks offer polyurethane sealers that provide a clear, durable finish, protecting your woodwork from abrasion and moisture. They are available in different sheens such as gloss, satin, semi-gloss, and flat/matte. These sealers are also available in different sizes, from 1 quart to 5 gallons. They can be applied using a brush, roller, pad, or by wiping on. Polyurethane sealers are known for their fast-drying, low-odor, and high foot traffic features, making them ideal for both indoor and outdoor woodwork.

Choosing the Right Clear Coat Sealer for Your Woodwork

Choosing the right clear coat for your painted wood furniture is crucial. There are numerous options, from sheens like flat, satin, semi-gloss, and glossy finish to oil-based and water-based clear coats. Some wood sealants might be harder but can leave a yellow haze on white pieces or hazy streaks on dark furniture. The best top coat is the one that you can’t tell is there. It's important to consider the type of furniture, its usage, and the environment it's placed in when selecting a clear coat.

Considerations for Indoor Woodwork

Indoor woodwork, such as furniture, benefits greatly from a clear coat sealer. It's crucial to choose the right sealer for high-traffic furniture pieces like dining tables, desks, and cabinets exposed to regular humidity. Dark paint colors, in particular, are prone to showing smudges and dust, so a clear coat provides necessary protection. If your painted wooden furniture will come into regular contact with water, food, or little fingerprints, a topcoat offers ultimate protection. My top recommendation for any kind of paint is Varathane Water-based Polyurethane, which provides a durable, waterproof finish.

Considerations for Outdoor Woodwork

When choosing a clear coat sealer for outdoor woodwork, consider factors like water and mildew resistance, UV protection, and environmental impact. Outdoor wood sealers should protect the wood from moisture that can cause rot, mold, or mildew. UV protection is also crucial to prevent damage from sunlight. Opaque or solid oil-based outdoor wood sealers with stabilizers offer the highest level of UV protection. Lastly, consider the environmental impact of the sealer. Check the product information to find out the level of VOCs contained in the sealant before deciding on a product.

How to Apply Clear Coat Sealers

Applying a quality clear coat sealer over basecoat color not only provides a superior gloss, it protects the color from fading and enhances appearance, scratch resistance, and overall durability. This standard operating procedure (SOP) covers the clear coat sealer application process. It's crucial to follow the correct application process to achieve a quality finish and ensure maximum adhesion capabilities.

Preparation of the Wood Surface

Preparing the wood surface is a crucial step in achieving a quality finish. The first step is to create a storyboard that confirms and illustrates your finishing procedure before you start the final project. It's important not to rush the process. Patience and careful attention to detail can significantly improve the quality of your final finish. If you're confident that surface preparation isn't the reason for your finishing issue, you may need to consider other factors such as stain/topcoat compatibility.

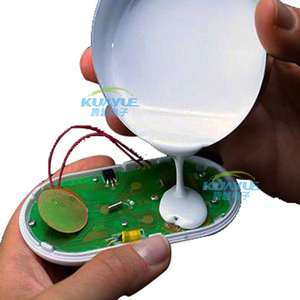

Application Process

Applying clear coat sealers involves a few key steps. Most clear finishes are applied with a brush, working in the direction of the grain of the wood. After it dries, sand lightly, then remove all the sanding dust and apply a second coat. For added durability, a third coat can be applied. To minimize brush marks and bubbles, 'tip off' each section of your project at a 45-degree angle and lightly run the bristles over the entire length of the wood. Be sure to mix in all material that may have settled to the bottom of the can. Avoid shaking as it will cause bubbles in the dried finish.

Drying and Curing Time

Understanding the drying and curing time of clear coat sealers is crucial for achieving the best results. The drying and curing times are influenced by the room's conditions, including temperature and humidity. Ideal conditions are 70°F/21°C and 50% humidity. Applying the sealer to a raw wood surface results in a shorter dry time, while applying over an existing finish increases it. It's important to ensure the first application of finish has completely dried before applying the next layer. For oil-based products, if it's no longer tacky and doesn't smell, it's dry. For water-based products, if it's cool to the touch, it's not dry.

Maintaining Your Sealed Woodwork

Maintaining your sealed woodwork primarily involves regular dry dusting, with damp wiping reserved for when the surface is dirty. Water can undermine a finish over time, causing more harm than dust or grime. Waxing is an age-old method of caring for finished wood and remains a viable option. A good paste wax is often a better choice than spray furniture polish containing oils or silicone. Avoid using soap and water for greasy surfaces; instead, use solvents like mineral spirits or turpentine. They won't harm the finish and prevent water from reaching the wood and damaging the finish.

Conclusion

In conclusion, clear coat sealers are an essential tool in preserving and enhancing the beauty of your woodwork. They offer protection against various damaging factors, and their choice should be based on the type of woodwork, its usage, and the environment it's placed in. The application process, while straightforward, requires careful attention to detail to ensure a quality finish. Regular maintenance of your sealed woodwork, primarily through dry dusting and occasional damp wiping, can extend its life and keep it looking its best. Whether you're a DIY enthusiast or a professional painter, understanding the nuances of clear coat sealers can help you make the most of your woodwork projects.