Introduction to CNC Composite Machines

CNC composite machines stand at the forefront of modern woodworking and fabrication, offering unparalleled precision in processing a variety of materials. These sophisticated devices are engineered to handle tasks from intricate cutting to detailed shaping, making them indispensable in the production landscape.

Types and Applications

The versatility of cnc composite machines is evident in their various types. From carbon fiber cnc routers designed for lightweight yet strong materials to alucobond cnc machines tailored for aluminum composite panels, the range is extensive. Applications span across industries, including automotive, aerospace, and construction, where precision and material integrity are paramount.

Features and Materials

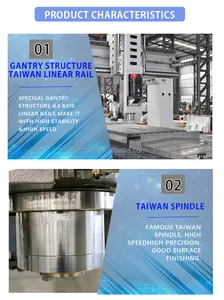

These machines are compatible with a plethora of materials, such as carbon fibre cnc routing for high-strength components and cnc dibond machines for durable signage and panels. Features of these routers include advanced control systems, variable speed settings, and dynamic axis movement, which accommodate a wide array of composite materials.

Advantages of CNC Composite Technology

The adoption of cnc composite technology brings numerous advantages to the production process. Efficiency in high-volume tasks, consistent output quality, and the ability to execute complex designs are just a few benefits. Moreover, the integration of cnc router carbon fiber technology allows for the creation of components that are both lightweight and high-strength, a demand in many high-tech sectors.

Choosing the Right CNC Composite Machine

Selecting the appropriate cnc composite machine involves considering factors such as material compatibility, size of the workpiece, and the specific end-use. For those requiring bespoke solutions, custom cnc carbon fiber machines can be sourced to meet unique production needs. It is essential to assess the machine's specifications, such as power rating, cutting style, and throughput rates, to ensure it aligns with the intended application.

Optimizing Production with CNC Composite Machines

In conclusion, CNC composite machines are a cornerstone in modern manufacturing, offering a broad spectrum of capabilities for various materials and applications. By carefully selecting the right machine based on specific requirements, businesses can significantly enhance their production efficiency and product quality.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4