Understanding Industrial Machinery for Dog Food Production

Industrial machinery for dog food production refers to specialized equipment crafted to streamline the large-scale manufacturing of pet food, predominantly tailored for dogs. These machines are intricately designed to execute a variety of tasks such as blending, grinding, extruding, dehydrating, and packaging, ensuring the requisite efficiency and uniformity vital for commercial pet food production. This equipment is customized to suit the needs of pet food manufacturers, spanning from small-scale enterprises to extensive production facilities.

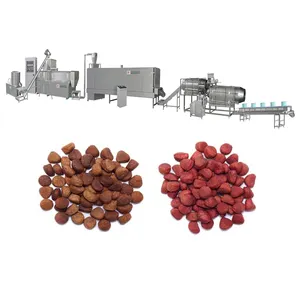

The fundamental concept underpinning industrial dog food production machinery is the conversion of raw materials into a final product that fulfills the nutritional requirements of dogs. This progression encompasses multiple phases, starting with ingredient preparation where raw components are received, scrutinized, and readied for further processing. The formulation of a well-balanced diet follows through mixing, amalgamating all essential nutrients in precise proportions. Subsequently, the blend is shaped into various forms and sizes, ranging from standard kibble to specialized shapes catering to different dog breeds and life phases.

The machinery employed in these processes is meticulously engineered for accuracy and effectiveness. It incorporates advanced functionalities like temperature management, pressure regulation, and material composition control to safeguard the nutritional value of the food and adhere to safety protocols. Notably, extruders play a pivotal role in producing various types of pet food by utilizing heat and pressure to cook ingredients into a semi-moist, easily digestible final product. Simultaneously, drying apparatus is utilized to eliminate post-cooking moisture, preserving the food's quality and extending its shelf life.

Industrial dog food production machinery stands as a critical component for enterprises striving to deliver premium pet food on a large scale. These machines are constructed to withstand the rigorous conditions of industrial settings, prioritizing productivity and safety. By automating diverse facets of the pet food production process, these machines not only economize time and labor but also elevate the overall quality of the food products.

Varieties of Industrial Machinery for Dog Food Production

The assortment of dog food production machinery mirrors the spectrum of products created to fulfill diverse dietary needs and consumer preferences. Here are several commonly utilized types within the industry:

-

Extrusion Machinery: This category encompasses equipment utilized in producing kibble and other extruded dog foods. Its primary components include the extruder, responsible for shaping raw ingredients into forms appropriate for pet consumption, and the dryer, which reduces moisture content to enhance shelf stability.

-

Mixing Equipment: Vital for blending various ingredients to craft a well-rounded and nutritious formula. Industrial mixers guarantee a homogeneous mixture of ingredients and are available in different capacities to suit tailored production lines.

-

Forming and Cutting Machinery: Following extrusion or mixing, the dog food is molded into the final product, which could range from bone-shaped treats to simple kibble. The machinery employed for this purpose includes cookie cutters or molds devised to create specific shapes.

-

Packaging Machinery: Packaging plays a pivotal role in safeguarding and conserving pet food. This encompasses primary packaging such as bags or pouches, along with secondary packaging like cartons or shrink wrap, maintaining product integrity during transit and storage.

-

Labeling Machinery: This machinery is structured to affix labels containing details such as ingredients, nutritional content, and pet food particulars to comply with labeling regulations and offer consumers transparent information.

Factors to Consider When Selecting Industrial Dog Food Production Machinery

The selection of appropriate industrial dog food production machinery is pivotal for any enterprise aiming to venture into or expand within the pet food market. When contemplating a purchase, businesses should assess factors such as the types of products they intend to manufacture, the required production capacity, and the specific functions each machine provides.

For instance, for businesses focusing on dry kibble production, it is essential to seek machinery proficient in managing high-temperature extrusion processes effectively. Conversely, if refrigerated products are on the agenda, equipment capable of cold processing techniques becomes imperative.

The scale of operations also influences machinery choice—larger facilities may necessitate sturdier and higher-capacity machines compared to smaller counterparts. Factors such as packaging requirements and desired automation levels should also be factored in during equipment selection.

Considering local service availability is crucial for continuous maintenance and support. Having access to suppliers offering immediate technical aid when required proves advantageous.

Ultimately, adherence to industry standards should dictate procurement decisions. Businesses must ascertain that the machinery complies with requisite regulatory standards concerning safety and product quality.

Insights into Industrial Dog Food Production Machinery on Alibaba.com

Alibaba.com showcases an extensive array of industrial dog food production machinery suitable for operations of varying scales or budget constraints. The platform's global reach ensures that businesses from over 190 countries can access a wide pool of suppliers offering cutting-edge equipment. Whether the aim is to manufacture dry kibble or wet food featuring specialized ingredients, Alibaba.com's diverse inventory caters to all formulations sought by contemporary pet owners.

The platform's commitment to facilitating seamless trade is evident through offerings such as mobile-friendly purchasing options and multi-language communication support, streamlining the buying process. Moreover, services like Trade Assurance provide reassurance by safeguarding payments until satisfactory delivery confirmation. This underscores Alibaba.com's dedication to delivering quality service and ensuring customer contentment.

By opting for Alibaba.com for your industrial dog food production machinery requirements, you not only gain access to a broad product selection but also collaborate with a marketplace prioritizing security, diverse offerings, and fostering dependable supplier relationships since 1999. This aligns seamlessly with the platform's mission of simplifying global trade, underscoring its role as an invaluable resource for businesses seeking to broaden their market presence while upholding efficiency and quality standards.

Frequently Asked Questions about Industrial Dog Food Production Machinery

What types of industrial dog food production machinery are available for large-scale production?

A range of machinery options exist, including mixing systems, extruders for kibble production, packaging machines for bulk and retail sales, and quality control devices to ensure adherence to product specifications.

How do I determine the right size and output capacity for my business?

Consider the scale of your operations, production volume, and future expansion plans. Machinery selection should align with present or anticipated production needs while accommodating potential growth.

What are the essential features I should look for in high-quality industrial dog food production machinery?

Key features encompass sturdy construction, stainless steel components for durability and ease of cleaning, precise control systems for consistent output, and compliance with industry standards for safety and hygiene.

Can industrial dog food production machinery be customized to specific dietary requirements?

Many suppliers offer customization options to cater to precise dietary needs, such as specific formulations or ingredient restrictions, ensuring alignment with your business's distinct requirements.

How can I ensure the quality of the industrial dog food production machinery I purchase?

Look for suppliers offering machinery with quality control certifications and a track record of producing high-caliber equipment.

Are there local service locations for installation and maintenance of industrial dog food production machinery?

Some suppliers provide local service centers for installation assistance and on-site maintenance within your facility. It is crucial to address these needs with the supplier before finalizing a purchase.

What after-sales services typically accompany the purchase of industrial dog food production machinery?

After-sales services may include online support and video technical aid. Certain suppliers might also offer field maintenance and repair services, a facet to confirm with the supplier pre-purchase.

How do the core component choices impact the performance of industrial dog food production machinery?

The caliber of core components like gearboxes and engines significantly influences machinery performance and durability. Superior quality components are imperative for machinery operating at high capacities.

Can I find machinery suitable for various stages of a dog's life cycle on Alibaba.com?

Absolutely, specialized machines designed for different life stages from puppies to adult dogs are available. These machines may feature age-appropriate kibble sizes and formulations tailored to the specific growth requisites of each stage.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4