Introduction to GI Wire Bending Machines

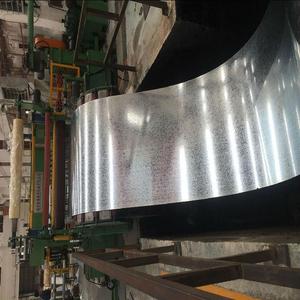

GI wire bending machines are specialized equipment used in the shaping of galvanized iron wires, which are commonly utilized in various industrial and construction applications. These machines are designed to bend wires with precision and efficiency, catering to the diverse needs of metalworking industries.

Types of GI Wire Bending Machines

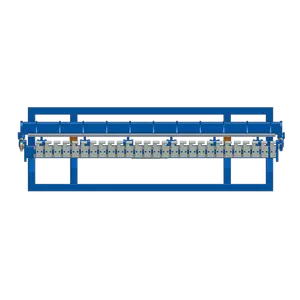

The market offers several types of GI wire bending machines, each suited for specific bending processes. The rotary draw bending machine is known for its precision, using a clamping mechanism and a rotating bend die to shape the wire. The roll bending machine employs fixed lower rollers and an adjustable upper roller to achieve the desired curvature. Similar in function to the rotary draw, the vector bending machine is another variant that provides efficient bending for GI wires.

Components and Functionality

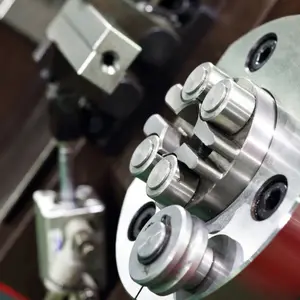

Understanding the components of a GI wire bender is crucial for selecting the right machine. The bend die is central to the machine, dictating the internal radius and the bend's shape. The clamp die secures the wire to the bend die, while the pressure die ensures the wire conforms to the bend die's path. Additionally, the wiper die plays a role in maintaining a smooth surface by preventing wrinkles during the bending process. Lastly, the mandrel is a critical component that supports the wire's interior, preventing collapse during the bending operation.

Applications and Features

GI wire bending machines are versatile, finding applications across various sectors such as construction, automotive, and manufacturing. These machines feature different bending capacities, speed settings, and angle precision, which allow for customization according to the specific requirements of a project. The adaptability of these machines to create complex wire shapes makes them invaluable in producing fittings, fixtures, and components.

Materials and Advantages

Constructed to handle the rigidity of galvanized iron, GI wire bending machines are built from durable materials, ensuring longevity and consistent performance. The advantage of using such specialized machinery lies in its ability to produce accurate bends, reduce material wastage, and increase production efficiency. The automation capabilities of these machines also minimize the need for manual labor, leading to a more streamlined manufacturing process.

Choosing the Right Machine on Alibaba.com

For businesses seeking to procure a GI wire bending machine, Alibaba.com offers a platform to connect with a variety of suppliers. The platform's extensive collection ensures that buyers can find a machine that aligns with their operational requirements and budget constraints, without the need to navigate through brand endorsements or promotional guarantees.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4