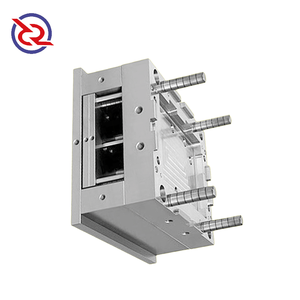

Introduction to Metal Stamping Die

A metal stamping die is a crucial tool utilized in various industries for shaping metal into desired forms. This process involves using cutting edges and a series of punches and molds to create intricate and precise parts from metal sheets. Highly regarded for their reliability and efficiency, metal stamping dies are essential for producing a wide array of components in automotive, aerospace, electronics, and consumer goods manufacturing.

Types of Metal Stamping Die

Metal stamping dies can be categorized into several types based on their design and purpose:

- Progressive Dies: These dies are designed to perform multiple operations in a single press cycle. Ideal for high-volume production, progressive dies feed the material through a series of stations, where different tasks such as cutting, bending, and forming occur.

- Compound Dies: Ideal for tasks that need both cutting and forming, compound dies achieve multiple operations in one stroke, streamlining the manufacturing process.

- Forming Dies: As the name suggests, forming dies are utilized to create parts through bending or shaping sheet metal without cutting it, making them perfect for sophisticated shapes.

- Blanking Dies: These are specifically designed to create flat pieces of metal (blanks) that can be used in further processing, focusing primarily on cutting out shapes from sheets.

Applications of Metal Stamping Die

The versatility of metal stamping dies allows them to be applied across a multitude of industries, which include:

- Automotive Industry: Metal stamping dies are extensively used to create various car parts such as brackets, body panels, and engine components. The precision offered ensures that each piece meets strict standards for safety and performance.

- Aerospace Sector: The aerospace field relies heavily on metal stamping to produce components that require high durability and precision, such as landing gears and fuselage parts.

- Electronics Manufacturing: From connectors to housings, metal stamping dies play a critical role in the production of electronic components that necessitate both intricate designs and reliability.

- Consumer Products: Many household items, from appliances to furniture, are created using metal stamping dies, demonstrating their functionality in everyday applications.

Advantages of Using Metal Stamping Die

Employing metal stamping dies brings a host of benefits, making them an invaluable choice for manufacturers:

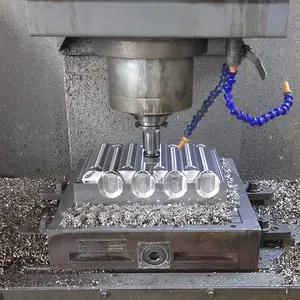

- High Efficiency: Metal stamping is capable of producing large volumes of parts in a short time, greatly enhancing productivity and reducing labor costs.

- Precision Manufacturing: The design and engineering behind metal stamping dies ensure that the finished products have tight tolerances, minimizing errors and enhancing quality.

- Cost-Effective: While the initial investment in dies can be significant, the longevity and reusability of quality dies help in lowering the overall manufacturing costs over time.

- Material Versatility: Metal stamping can be performed on various metals such as steel, aluminum, and copper, allowing for a wide range of applications and customizations.