Understanding Packing Cooling Towers

A packing cooling tower is an integral component in various industrial processes, designed to remove heat from water used within these systems. This category encompasses a range of designs and capacities, tailored to meet the specific cooling requirements of different operations. The core function of these towers is to facilitate the reduction of water temperature by releasing waste heat into the atmosphere, thus maintaining the efficiency of the industrial cooling systems.

Types of Packing Cooling Towers

There are several types of cooling towers to consider, each with unique features and operational principles. Crossflow and counterflow models represent two primary configurations. In a crossflow cooling tower, air moves horizontally across the falling water, while in a counterflow design, air flows vertically upward against the descending water. The choice between these types depends on the specific thermal performance requirements and spatial constraints of the facility. Additionally, hyperbolic cooling towers are recognized for their natural draft capabilities, making them suitable for large-scale industrial applications.

Applications and Features

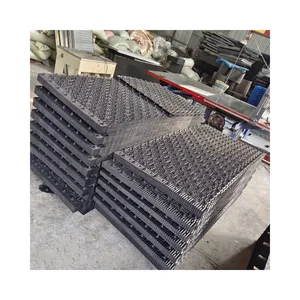

The application of industrial cooling towers spans numerous sectors, including power generation, manufacturing, and HVAC systems for large buildings. Key features of a packing cooling tower include its heat exchange efficiency, the material of construction which often comprises corrosion-resistant metals or composites, and the type of fill or packing used which significantly influences the tower's performance. The packing material increases the surface area for heat exchange and is selected based on its thermal conductivity, resistance to fouling, and durability.

Materials and Advantages

Materials used in the construction of cooling tower systems are chosen for their resilience and longevity. These can range from galvanized steel to fiberglass-reinforced plastics. The advantages of utilizing a packing cooling tower include improved water conservation by recirculating cooled water, energy efficiency due to advanced heat exchange materials, and a reduced environmental impact through the use of evaporative cooling rather than refrigerants.

Selection Considerations

Selecting the right cooling tower packing is crucial for optimal performance. Factors such as cooling capacity, wet bulb temperature, and the quality of the circulating water must be considered. Additionally, the design of the cooling tower fill plays a pivotal role in the efficiency of the tower, with options like splash and film fills available to cater to different cooling needs.

Maintenance and Sustainability

Maintenance of a cooling tower is essential for sustained operation. Regular cleaning of the packing material, inspection of the water distribution system, and monitoring of the mechanical components ensure the longevity and efficiency of the tower. Sustainability in cooling tower operations is achieved through the use of energy-efficient motors, drift eliminators to minimize water loss, and environmentally friendly packing materials.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4