Popular in your industry

Related Searches:

Top categories

About resin printing machines

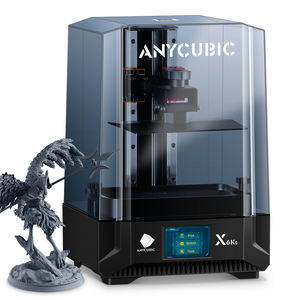

Introduction to Resin Printing Machines

Resin printing machines, also known as resin 3D printers, are cutting-edge devices that utilize liquid resin to create high-precision 3D models. These machines are widely used in various industries such as engineering, healthcare, jewelry making, and more. The technology behind resin printing allows for intricate designs and smooth finishes, making it a popular choice for businesses looking to produce detailed prototypes or end-use parts.

Advanced Features of Resin Printing Machines

One of the key features of resin printing machines is their ability to produce parts with exceptional accuracy and surface quality. These machines use a process called stereolithography (SLA) or digital light processing (DLP) to cure liquid resin layer by layer, resulting in precise and detailed objects. Additionally, resin printing machines offer a wide range of compatible resins, including dental resin 3D printer materials, ensuring versatility in materials for different applications.

Enhanced Performance with Elegoo Wash and Cure

For businesses looking to streamline their post-processing workflow, integrating Elegoo wash and cure systems with resin printing machines can significantly enhance efficiency. The Elegoo washing and curing machines automate the cleaning and curing processes, ensuring thorough cleaning of printed parts and uniform curing for optimal mechanical properties. This combination results in faster turnaround times and improved overall productivity.

Choosing the Right Resin Printing Machine

When selecting a resin printing machine for your business, consider factors such as build volume, XY resolution, layer height, and compatible resins. Machines with larger build volumes are suitable for producing bigger parts or multiple prototypes simultaneously. High XY resolution and minimal layer height contribute to the overall detail and surface finish of the prints. Additionally, having compatibility with a range of resins, including 3D printer wash and cure materials, allows for versatility in material selection.

Maintenance and Care for Resin Printing Machines

Proper maintenance is essential to ensure the longevity and performance of resin printing machines. Regularly cleaning the vat and build platform, replacing the resin tank, and calibrating the machine are crucial maintenance tasks. It is also important to store resins properly to prevent contamination and ensure print quality. Following manufacturer guidelines for maintenance and using high-quality resins, such as resin wash and cure materials, can help prolong the lifespan of the machine.

Optimizing Production with Resin Printing Machines

Businesses can optimize their production processes by leveraging the capabilities of resin printing machines. These machines enable rapid prototyping, allowing for quick iterations and design modifications. The high level of detail and accuracy achieved with resin printing makes it ideal for creating intricate models and functional prototypes. By incorporating Elegoo wash and cure systems into the workflow, businesses can streamline post-processing tasks and deliver high-quality finished parts efficiently.

Investing in Resin Printing Machines for Business Growth

Integrating resin printing machines into your business operations can drive innovation, reduce time to market, and enhance product development processes. The ability to produce complex geometries and detailed parts with resin printing opens up new design possibilities and accelerates product iterations. By investing in advanced technologies like resin 3D printers and complementary wash and cure systems, businesses can stay competitive and meet the demands of a fast-paced market.

Exploring Diverse Applications of Resin Printing Machines

Resin printing machines find applications across various industries, including automotive, aerospace, healthcare, and consumer goods. In the automotive sector, these machines are used for rapid prototyping of components and functional testing. In healthcare, resin printing enables the production of customized medical devices and anatomical models. By understanding the diverse applications of resin printing machines, businesses can harness the full potential of this advanced technology.

Driving Efficiency with Resin Printing Technology

The efficiency and precision offered by resin printing machines make them a valuable asset for businesses seeking to optimize their manufacturing processes. Whether it's creating intricate jewelry designs, functional engineering prototypes, or detailed architectural models, resin printing technology delivers superior results. By embracing the capabilities of resin printing machines and integrating complementary technologies like Elegoo washing and curing systems, businesses can elevate their production capabilities and meet the demands of a competitive market.

Conclusion

In conclusion, resin printing machines represent a significant advancement in additive manufacturing technology, offering businesses unprecedented precision, detail, and versatility in 3D printing. By understanding the key features, benefits, maintenance requirements, and application areas of resin printing machines, businesses can make informed decisions about integrating this technology into their operations. With the right equipment, such as dental resin 3D printers and resin wash and cure systems, businesses can enhance their production processes, drive innovation, and achieve growth in their respective industries.