Popular in your industry

Related Searches:

Top categories

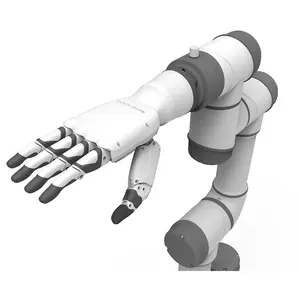

About robot bottle gripper

The robot bottle gripper represents a pinnacle of automation technology, crafted to bolster efficiency across diverse industrial realms. This cutting-edge apparatus is adept at manipulating bottles with both precision and delicacy, rendering it an essential element in contemporary manufacturing and packaging operations. The robot bottle gripper integrates flawlessly with systems such as pick-and-place arms, palletizing manipulators, and a variety of robotic solutions, delivering heightened productivity and steadfast reliability.

Types and Characteristics of Robot Bottle Grippers

Available in a multitude of designs, robot bottle grippers possess distinct features tailored to meet specific operational demands. While some are equipped with a singular gripping arm for simple tasks, others boast multiple arms to execute intricate maneuvers. Grippers with adaptable fingers can manage bottles of varying sizes, and those with non-contact gripping technology are ideal for handling in delicate or sterile conditions. A thorough analysis of a production line's requirements is vital for choosing the appropriate gripper, be it for lightweight plastic or hefty glass containers.

Structure and Operational Components

Comprising several synchronized components, the robot bottle gripper is built around a motor that supplies the requisite power. A programmable logic controller (PLC) enables precise command over operations, while the gearbox converts motor power into the desired speed and torque. The gripping mechanism may consist of pneumatic cylinders, vacuum cups, or mechanical fingers, all designed to secure bottles without causing harm. Integrated sensors within the gripper relay feedback on grip strength and bottle positioning, ensuring smooth and efficient system performance.

Materials and Properties

The construction of robot bottle grippers involves materials selected for their robustness, longevity, and product compatibility. Metals like stainless steel are favored for their sturdiness and corrosion resistance, whereas softer substances such as silicone are utilized for gripper pads to avert bottle damage. Lightweight and flexible advanced polymers are also employed. These material choices guarantee the gripper's endurance under continuous industrial use while preserving bottle integrity.

Business Usages and Applications

In sectors where bottling is central to production, such as the beverage, pharmaceutical, and cosmetic industries, robot bottle grippers are indispensable. They expedite the movement of bottles through various stages—filling, capping, labeling—safely and swiftly. By optimizing workflows, diminishing manual labor, and curtailing product damage during handling, these grippers add value to businesses. For example, in pharmaceuticals, the precision of robot bottle grippers is critical for maintaining vial sterility, thereby ensuring product safety.

Functions and Task Performance

A robot bottle gripper's primary role is to securely grasp and manipulate bottles of diverse forms and sizes. Capable of tasks such as sorting, orienting, and placing bottles onto conveyors or into packaging, these grippers can also be programmed for assembling packaging components, necessitating both accuracy and a gentle touch to prevent product damage.

Features and Unique Selling Points

Key attributes of robot bottle grippers include their versatility and precision. Many models feature quick-change tooling and programmable grip patterns for effortless transitions between bottle types. The most advanced models are equipped with force feedback systems that dynamically adjust the grip to accommodate fragile items. These functionalities distinguish them from competitors, offering users enhanced flexibility and control in bottling operations.

Benefits and Positive Outcomes

Integrating a robot bottle gripper into a production line yields a plethora of advantages. It mitigates the risk of workplace injuries related to manual handling and heightens the uniformity of product handling, thereby elevating product quality. The efficiency improvements afforded by these grippers can translate into substantial cost reductions and increased throughput, securing a market advantage.

How to Use and Operate Effectively

To operate a robot bottle gripper effectively, one must program the PLC to match the task specifics. Operators are tasked with setting accurate parameters for grip strength, speed, and movement patterns. Continuous training and familiarity with the system's capabilities are imperative for staff to exploit the gripper's full potential.

How to Choose the Right Model

Choosing the correct robot bottle gripper model necessitates a deep understanding of the production line's particular needs. Considerations should include the material, shape, and weight of the bottles, as well as the operational environment of the gripper. Consultations with manufacturers and scrutiny of machinery test reports are advisable to make an informed selection.

How to Clean and Maintain

Maintaining a robot bottle gripper in prime condition is crucial for its longevity. Routine cleaning of the gripping mechanism to eliminate debris or residue, coupled with lubrication of moving parts for seamless operation, is essential. Adhering to the manufacturer's maintenance schedule recommendations is key to averting malfunctions and prolonging equipment lifespan.

How to Install

Installation of a robot bottle gripper should be executed by professionals. The process entails affixing the gripper to the robotic arm, connecting it to the power and control systems, and calibrating the sensors and gripping mechanism. Proper installation is essential for the gripper's optimal function and seamless integration with the existing production infrastructure.

Target Audience and Meeting Needs

The intended clientele for robot bottle grippers spans industries where bottling is a frequent and critical operation. These devices cater to enterprises seeking automation solutions that enhance efficiency, bolster safety, and guarantee product quality. From boutique craft breweries to expansive pharmaceutical firms, the adaptability of robot bottle grippers renders them suitable for an extensive array of applications.

What are the local service locations for support?

Companies contemplating the adoption of a robot bottle gripper can take solace in the availability of support across the globe. Nations such as Thailand, Turkey, India, Russia, and the United States host local service centers where businesses can obtain technical assistance and maintenance services.

What after-sales services are provided?

Post-purchase, robot bottle gripper customers can anticipate a suite of after-sales services. Offerings include video technical support, online help, and on-site maintenance. For more intricate challenges, engineers stand ready to provide overseas machinery service, ensuring minimal downtime and the continuity of operations.

How does the robot bottle gripper adapt to different bottle types?

The robot bottle gripper's ability to adjust to a variety of bottle types showcases its sophisticated engineering. Through programmable settings and modifiable components, these grippers can be fine-tuned to accommodate an extensive spectrum of bottle shapes, sizes, and materials. This adaptability permits businesses to employ a single gripper across multiple product lines, optimizing investment returns.