Rubber membrane roofing is a special type of roofing material that uses rubber as the main component and has excellent weather resistance, corrosion resistance, aging resistance, and waterproof performance. The flat roof rubber membrane is made of natural rubber or synthetic rubber as the base material, added with an anti-aging agent, anti-ultraviolet agents, and other additives, and processed by a special process. Its surface is usually covered with a protective film to enhance its weather resistance and waterproof performance.

The Feature of the Rubber Membrane Roofing

In terms of material characteristics, the EPDM rubber roofing membrane has remarkable elasticity and flexibility, which enables it to adapt to the deformation and displacement of buildings and reduce the stress caused by temperature difference and settlement. The rubber membrane has good weather resistance and can maintain its performance and appearance under different climatic conditions. Under prolonged exposure to wind, rain, and sunlight, its performance is not easily affected and is not prone to aging. The EPDM roof membrane has good corrosion resistance and can resist the erosion of various chemicals. For acid, alkali, salt, and other chemicals, the rubber membrane does not easily corrode and can protect the roof materials from damage.

The EPDM waterproofing membrane has good aging resistance and can maintain its performance and appearance during a long time of use. It has a long service life and is not prone to cracking, powdering, and other phenomena. The waterproof rubber membrane has good waterproof performance, which can effectively prevent moisture penetration and protect the interior of the building from moisture and mildew. Its waterproof performance is stronger than traditional waterproof materials, which can effectively improve the service life and safety of buildings. The installation and maintenance of the rubber membrane is relatively simple and generally only needs to follow the installation guide provided by the manufacturer. At the same time, the repair and replacement of the rubber membrane is relatively convenient, which can reduce the maintenance cost.

Installation Precautions of the Rubber Membrane Roofing

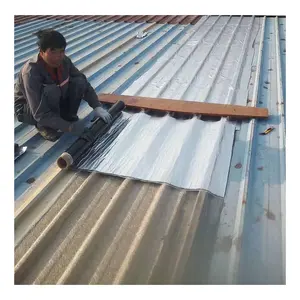

Before installation, the tpo rubber for roofing should be checked for any damage or defects. The construction temperature should be controlled to avoid installation in adverse weather conditions such as high temperatures, strong winds, and rainy days. The rubber membrane shall be protected from mechanical damage and direct sunlight during transportation and storage. When overlapping and fixing, special adhesives or fasteners should be used, and the installation instructions provided by the manufacturer should be followed. During installation, keep the rubber membrane flat and naturally sagging to avoid wrinkles or distortion. When closing, the closing area should be folded inward to enhance its waterproof performance. After installation, a comprehensive inspection should be conducted to ensure that there are no defects or omissions.

The Maintenance of the Rubber Membrane Roofing

During the use, the rubber membrane shall be checked regularly. If aging, damage, or detachment are found, they should be repaired or replaced in a timely manner. When cleaning and maintaining, a soft cloth or sponge should be used to gently wipe, avoiding the use of strong acids, bases, or organic solvents. During overhaul, maintenance or other operations, attention should be paid to protecting the rubber membrane from mechanical damage or chemical corrosion. During use, attention should be paid to avoiding prolonged accumulation of water or pressure from heavy objects to prevent damage or deformation. During use, attention should be paid to keeping the rubber membrane dry and ventilated to avoid mildew or decay.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4