Popular in your industry

Top categories

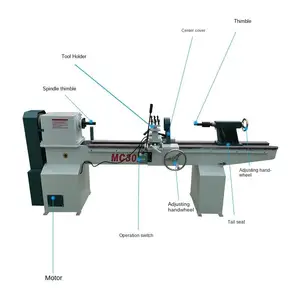

About wood lathe

An instrument in the field of woodworking, the wood lathe enables the creation of symmetrical wooden items by means of rotational carving techniques. Its applications range from the production of valuable objects to decorative objects, displaying exquisite craftsmanship. The development of wood lathes has produced multiple variations, from small, hobbyist-friendly machines to sturdy, industrial-grade devices like the grizzly wood lathe, designed for professional use.

Some types of wood lathes

Wood lathe machines have different models for different woodworking needs. Benchtop lathes usually feature a small size, which contributes to their portability and makes them ideal for projects with more precision and control. These are ideal for projects like pens and spindles. Floor-standing lathes are bigger and stronger, so they're better for turning large pieces like table legs and bowls. They often have variable speed controls and more power to handle heavy work. In addition to benchtop and floor-standing models, there's also the midi wood lathe. This type blends the ease of a benchtop lathe with the capacity and sturdiness of a floor-standing lathe. It's ideal for experienced woodworkers who work on diverse projects.

Moreover, there are specialized lathes tailored to specific woodworking tasks. For instance, pen lathes are designed for making pens, and bowl lathes are crafted explicitly for shaping bowls. Digital wood lathes provide precise and user-friendly controls. They allow for programming-specific turning steps, such as speed adjustments and tool movements. This automation increases efficiency and accuracy in woodworking projects. Different types of lathes are available to meet the varied needs and skill levels of woodworkers, depending on their projects.

Modern features of wood lathes

Modern wood lathes come equipped with cutting-edge technologies that improve productivity, user safety, and flexibility to meet various project needs. Precise spindle speed modification is made possible by variable speed control mechanisms, which are essential for both the removal of coarse material and the completion of fine details. Adjustable tool rests give wood turning tools a steady surface to work on during the carving process, which is necessary to get precise cuts. Extension beds can be attached to increase the capacity of lathes for tasks requiring longer lengths, like balusters or table legs. High-end machines, like the grizzly wood lathe, are designed to reduce vibration and frequently have digital speed readouts. This results in a smoother operation and better-quality end products. These features not only increase productivity but also contribute to overall safety during woodworking and make this an ideal companion for the worker.

Professional advantages of wood lathes

Wood lathes are valuable for a wide range of tasks, including the creation of ornamental and functional wooden products. Small-scale objects such as pens, bowls, and other finely detailed components are ideal for small wood lathes. On the other hand, larger lathes can be used to fabricate massive objects such as architectural elements and furniture parts. The use of specialized wood lathes to create wood lathe tools, such as gouges, chisels, and scrapers, each made for a particular woodworking method, dramatically increases the usefulness of wood lathes. This adaptability enables craftspeople to turn raw timber into exquisitely made works of art or functional goods.